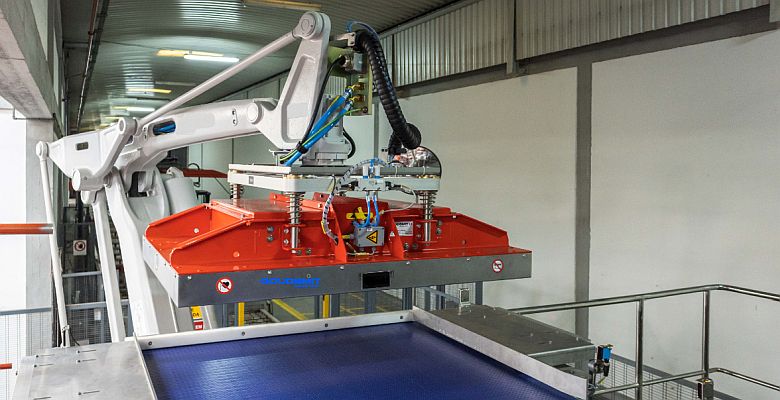

The easy maintainable magnet by Goudsmit Magnetics is suitable for palletising and depalletising cans, aerosols, canisters and glass jars with steel lids.

The palletising magnet design, adapted by Goudsmit Magnetics in Waalre (Netherlands), consists of modules that vary in design. The magnet is used by integrators, packaging companies, food producers and pharmaceutical companies, among others.

The modular construction offers users a number of choices that save on an extra robot and manpower. For example, there is a lightweight version or a 'spring suspension unit'. This is a spring suspension unit that provides a flexible spring path, prevents product damage and enables correct positioning. The options vacuum system and/or pallet gripper ensure that actions such as removing a pallet, laying down or removing an intermediate sheet between a layer of cans can be carried out by one robot. The costs saved by the user ensure a quick return on investment of this new system.

Design

The central scissor mechanism consists of two cylinders that ensure an even switch-on and switch-off of the palletising magnet and drive the sheet in one go. This ensures a parallel force distribution, which is not always the case when four cylinders are used. The integrated vacuum system is designed to pick up and process any size and type of intermediate sheet.

The parallel switching mechanism guarantees a low-maintenance, trouble-free production process, even when loaded unevenly, for example when picking up an uneven layer. The magnet can be equipped with several pole systems. This makes the field stronger at the surface for light cans or aerosols and deeper for heavier loads, such as filled (canning) cans.

Safety and durability

The palletising magnet is easy to operate with pneumatics and is fitted with sensors for on/off detection. The spring suspension unit makes positioning easy and prevents product damage. In addition, it is equipped with sensors that prevent tilt (skidding) and jamming, as well as crashing of the robot in case of irregularities.

In an automated environment, safety is an important aspect. Because it works with a permanent magnet, the load remains on the magnet even when energy is lost. This reduces the chance of unsafe situations, as does the chance of damage. In addition, switching with only an air pressure pulse makes it a sustainable and energy-efficient solution.

The palletising magnet has a long life, is maintenance-friendly and uses little air. Any wear parts are easy to replace. The company supplies the lightweight palletiser magnet to various customers worldwide. Even when the system is in continuous operation 24 hours a day, maintenance is minimal.

Photo: Goudsmit Magnetics