New automation technology allows industrial robots to visually classify work and perform tasks autonomously.

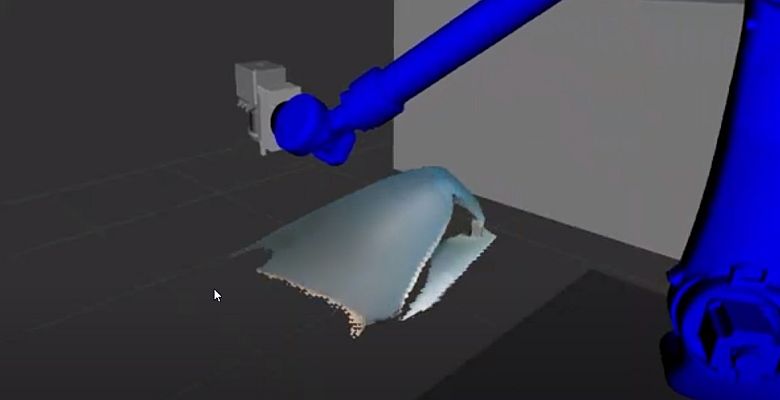

The Southwest Research Institute (SwRI) in San Antonio, Texas, is developing new image processing tools for robotics to automate aircraft surface preparation. The robots can autonomously scan, sand and prepare surfaces on aircraft and other machines. The technology can be applied to grinding, painting, polishing, cleaning, welding, sealing and other industrial processes.

The technology increases process repeatability, improves part quality and reduces rework. It also reduces human exposure to hazardous substances and unergonomic environments.

Machine learning

The system uses machine learning algorithms and classification software developed by SwRI. They can work together with open-source tools such as Scan-N-PlanTM and ROS 2, the latest version of the open-source robot control system.

Scan-N-Plan, an ROS-Industrial technology, uses machine vision to scan parts and creates 3D mesh data. Robots use these to plan tool paths and process trajectories while performing real-time process monitoring. SwRI works closely with the ROS-I project to maintain its software repository and expand open source automation solutions.

Using these open source tools with the custom software, the developers in San Antonio have developed a solution that intelligently classifies regions and textures of part surfaces at different stages of the work.

Machine vision

The solution includes custom machine vision algorithms that allow robots to apply different media. This can be done with varying pressure based on the amount of surface work required. Feature-based processing is also enabled by additions that use semantic segmentation approaches. This allows the right tool to be applied to the right feature, for example, cutting versus sanding. SwRI talks about breakthroughs that will help prevent robots from over-sanding or grinding metal surfaces.

The project demonstrates the advanced features of ROS 2 while providing an initial framework for building out additional applications. It is also an open source example for teaching and training those interested in developing advanced solutions using ROS.

In doing so, SwRI provides proven solutions using this framework for business and government. The technology is suitable for a wide range of applications, for both stationary cell-based systems and mobile solutions.

Photo: SwRI